Church Clock

Saint Peter’s Clock was not fitted when the church was built in 1881. It was fitted seventeen years later in 1898.

The clock was to be known as ‘The Warbeck Memorial Clock’ in memory of Rev. Edmund Warbeck B.A.who was vicar of Stapenhill from 1875 to 1897. There is a memorial tablet in the church in memory of his great contribution to the parish which reads:

THE CLOCK ON THE TOWER WAS ERECTED

BY PAST AND PRESENT PARISHIONERS

TO COMMEMORATE THE

FAITHFUL LABOURS, FOR 28 YEARS,

OF REV. EDMUND WARBECK B.A.

IN THE PARISH OF STAPENHILL

DIED MAY 9TH, 1897

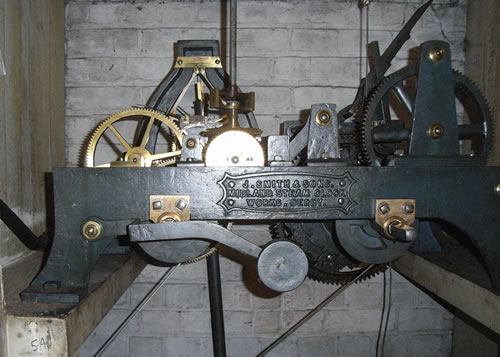

The Clock itself was made It was made in Queen Victoria’s 60th Anniversary year (1897 – 1898) by John Smith & Sons Limited Of Derby, who were still in business in 2000.

The clock and bell cost £186 which, to put things in perspective, would buy a reasonable house at the time. This was a very large amount of money to raise but there were several generous contributions which is testament to how revered and respected Edmund Warbeck was.

The type of clock is a ‘Double three legged gravity escapement’, which probably won’t mean much more to you than it did to me, but significantly, it is exactly the same mechanism as employed in the Big Ben tower!

There are four dials, each 6 feet in diameter; the yearly inspection fee in 1900 was £3.10s.0d (£3.50p). Around 1920 the clock faces were painted and gilded at a total cost of £34 0s 0d. An estimate for the same work in 1995 was £2,150 (plus VAT)

The clock mechanism is enclosed in a wooden case to protect it from its dusty environment.

To the left of the cabinet are two large weights; the smaller one is used for the actual clock mechanism, the larger one is used for the chiming mechanism. Below, is an escape hatch and on the floor below, is a large container of fine sand to catch them should they fall to prevent them from crashing through a series of floors and into the main foyer.

The cables actually failed in around 1991 whilst the clock was being wound to put this safety measure to the test!

The mechanism itself has two separate winders. The left hand half is the clock mechanism and below it is the pendulum used to keep the time. Its swing takes one and a quarter seconds which means that it has 48 ‘ticks’ per minute. The right hand half controls the chime which strikes once for each hour, on the hour.

Winding the clock itself comprises fitting a handle in turn to each half and winding the weights to the top. It takes approximately seven days for the weights to lower back to the floor. A small weight within the cabinet provides energy whilst the clock is being wound so that it doesn’t lose time during the actual winding.

A simple gearing mechanism drives a vertical shaft rod to the clock chamber above where a very simple gearbox drives four horizontal shafts, one to each face.

The bell chamber was actually built to accommodate eight bells but, due to some shift in the tower, an architect inspection recommended that a single bell should be installed. This is not too surprising when you consider that the bell that is there weight over eight and a half hundred weight.

The bell is just under three feet diameter and strikes a note of B sharp. The bell may be struck in three ways; by a hand striker, by the clockm mechanism or by the bell-chord (or by swinging the large wheel to which it is attached.

The bell was cast in 1898 by Charles Carr of Smethwick, one of the premier bell manufacturers.

Passers by have for well over a hundred years, checked their watches against the very familar tower without a thought for the mechanism that makes it possible.